Is Your Generator Ready For Winter?

As we get ready for a harsh Winter, some of us plan to rely on our backup generators to kick on if the power goes out. But, what if your generator fails to run in an emergency?

I have been a diesel and generator tech for over 10 years and started my own mobile repair business, Wyld West Repair, in 2023. I’ve worked for CAT and other generator companies as well as managed/operated the shop at an equipment company. I service the Bighorn Basin for anything from diagnostics to roadside repairs and some bigger projects for diesel and commercial equipment.

With winter coming soon, I am now offering generator repair and maintenance services in addition to mobile equipment repairs. So, I would like to share a few important things about why your generator might fail in an emergency. Having a better understanding on how your generator works and how to troubleshoot it could help prevent costly repairs or replacements in the future.

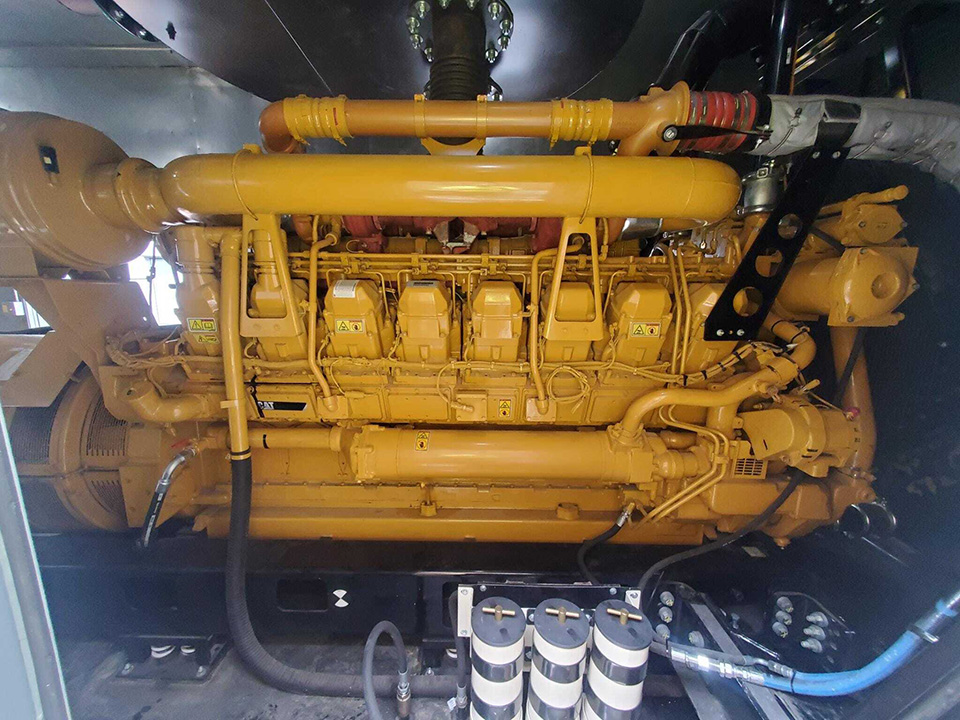

Backup generators are tasked with starting and providing emergency backup power within seconds of a utility power outage.

In order to accomplish peak performance and reliability, the genset must be properly maintained. These engines must reliably start, reach operating rpm (usually 1,800 rpms) and provide power. The major reason a generator fails is the result of poor or no maintenance.

The most critical of utility outages usually come in the most severe weather conditions. Severe cold or heat are prime conditions that will expose genset problems and result in failure to provide emergency power.

The most common root causes of failure

– Lack of battery maintenance. A majority of the time, an old battery will cause your generator to fail. I recommend replacing your battery every 3 yrs. With units that have onboard battery chargers, the charger may have failed or gone unnoticed. Additionally, corroded connections/cables cause high resistance or broken/open paths and prevent the battery from supplying power to the starter and results in a no start condition.

– Restricted air filters. Dirty air filters, especially in dusty environments, are just as bad for your generator as it is for your car. Unfortunately, generator enclosures are the perfect environment for mice and other rodents. Air filters can be the ideal spot for them to nest, preventing the engine from getting the proper amount of air it needs to operate. Air filters should be regularly checked and cleaned as needed, and replaced every 3 yrs, or earlier if need be.

– Oil and coolant levels. Much like your vehicle, your generator cannot operate without oil and coolant for liquid cooled engines. Most residential units are air cooled, much like a lawn mower. Proper oil level and condition is essential for operation and life expectancy of the genset. Oil changes are recommended every 250 hours or yearly.

– Coolant level and condition. Low coolant level can prevent the generator from running and allow for overheating and shutdown conditions if not maintained. Improper coolant condition can also lead to premature radiator failure. Coolant that has inadequate freeze protection can result in a catastrophic failure to components including the engine. The coolant and thermostat should be changed every 3 years. Block heaters need to be inspected for proper operation. Inoperable heaters will lead to no start conditions in cold weather. Conversely, heaters with malfunctioning thermostats can lead to overheating conditions causing premature block heater and hose failure.

– Belts and hoses. Larger units that are liquid cooled and have belt driven fans and components need to have the belt condition and tension inspected regularly. Belts should be replaced if they are cracking or deteriorating and should be changed at the manufacturers recommended intervals or every 3 years. Oil and coolant hoses should also be inspected regularly. Clamps should be checked for tightness and replace hoses if they are cracked or leaking. Block heater hoses and radiator hoses should be replaced every 3 years.

– Fuel supply issues. Whether your generator is natural gas, propane, diesel or gas, fuel supply issues can and will affect performance. Diesel generators need fuel filters replaced yearly or every 250 hours. And the water needs drained from the separators monthly. Diesel generators also need fuel supply tanks monitored for proper fuel condition. Natural gas and propane gensets need adequate fuel pressure from the supply tank/line in order to function properly. Damaged or leaking supply piping, dirty regulators, and improper installation all can affect the flow of the gas and affect operation.

– Air flow. Gensets need air to function, for combustion to run, and to cool the generator and engine. Enclosures that are surrounded or blocked by vegetation/bushes, buildup of dust and dirt, or improperly installed can lead to premature component failure, generator shutdown/no start conditions, overheating issues and improper performance.

– Load Conditions. Lastly, larger gensets (particularly diesel) that are continuously operated at low or no load conditions are prone to wet stacking. This can lead to oil consumption issues, excessive exhaust smoke, and poor performance. Load banking is an essential maintenance task on larger gensets that do not regularly see above 50% load. This test also ensures proper generator operation and helps to prevent wet stacking.

If you are concerned about the condition of your generator, please give me a call to schedule a time to have it checked and assessed for maintenance.

Billy Burns

Wyld West Repair

Billy Burns is the owner and operator of Wyld West Repair - a highly recommended mobile equipment repair service in the Bighorn Basin. With over 10 years experience, he brings a high level of expertise in the diesel and commercial equipment industry as well as extensive knowledge for residential and commercial generators. He’s a husband of 14 years, father to two boys and enjoys hiking, hunting, and camping with his family.